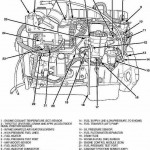

Here’s the dust cover that needs to be removed to access the governor springs Once the dust cover is removed you’ll need to turn the motor over till a set of springs is lined up perfectly in the opening … there are 2 sets of springs they are mounted opposite of each other Here’s how […]

Post Your Successful Diesel Mods At Dieseldatabase

Have you completed a successful mod on your diesel truck? and did you take pictures and discovered tips that might help others? Your post is welcome here. All you have to do is register on this site. Then contact us via the the contact form on the ABOUT page (see menu), letting us know you […]