Click the link below for the pdf version of Stewart Warner Quad Console Pod Install Sheet Stewart Warner Quad Console Pod Install Sheet [thanks to Stewart Warner used with permission]

Pages

Categories

Archives

This is a comparison between a Vulcan fitting and your stock banjo set up. The Vulcan Fittings are CNC Stainless Steal and are avalible with a tap in them for running a Fuel Pressure gauge. Vulcans Fitting replace The Stock Banjo’s at the following locations : VP44 inlet Fuel Filter Housing Inlet Fuel Filter Housing […]

Work Performed On: 2002 CTD Estimated time of Completion: 2 Hrs Parts Required: Brake Shoes, Brake Cleaner, Brake Fluid, Little Helper Tools Required: 1/2 Inch Drive Ratchet, Cheater Pipe, 2 Extensions, 15/16 6 pt Socket, 7/32 Allen Wrench, 16 MM 12 pt Socket, Big Strait Screw Driver, Floor Jack, Penetrating Oil, 3/8 inch wrench Product […]

The simple explanation: a waste gate limits the maximum boost generated by the turbocharger. How it works and what it does: The waste gate uses a pressure activated diaphragm and rod to operate an exhaust bypass around the turbocharger and thus limit the maximum boost that the turbocharger can produce. This permits an engine manufacturer […]

This documentation is intended to be used as a visual overview only and is not meant to be used as a replacement for a service manual. Please consult your Dodge service manual for complete instructions on the removal and re-installation of an injection pump The truck in this project is a 2000 Dodge Ram 3500 […]

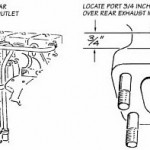

See Universal Installation Guide for Installation on Turbo Down Pipe 1. Remove turbo from exhaust manifold. 2. Stuff a small shop towel or rag 4 to 5 inches into the rear exhaust manifold passage (see pic below) through the turbocharger mounting flange. This is to prevent chips from entering the manifold while drilling and tapping. […]

With this guide we have a donor charger so Removal of the charger is not included Refer to the Charger Swap Guide for further information Completion time: Less than 2 Hours Here’s a 16cm Holset Exhaust Housing Here’s the Exhaust Gasket Here’s the Oil Return Line Gasket Here’s the donor charger This set up is […]

Significant interest, and LOTS of misconception surrounds bypass oil filters in general – and the Frantz TP filters especially, tho’ the same general construction is also used for the several paper towel bypass filters as well. Bypass oil filtration differs from the stock full-flow filters used on all modern engines, including our Cummins, in that […]

Post Your Successful Diesel Mods At Dieseldatabase

Have you completed a successful mod on your diesel truck? and did you take pictures and discovered tips that might help others? Your post is welcome here. All you have to do is register on this site. Then contact us via the the contact form on the ABOUT page (see menu), letting us know you […]