Significant interest, and LOTS of misconception surrounds bypass oil filters in general – and the Frantz TP filters especially, tho’ the same general construction is also used for the several paper towel bypass filters as well.

Bypass oil filtration differs from the stock full-flow filters used on all modern engines, including our Cummins, in that whereas virtually ALL pressurized engine lubricant must flow thru the stock full flow filter, and then on to various engine parts, only a very SMALL volume of diverted lube flows thru a bypass filter, and then is returned to the crankcase.

The far slower volume, and reduced lubricant pressure, combined with the far more dense filter material used in bypass filters, provides much improved filtering than the full-flow filter, but at much slower pace. Here’s photo of the restriction as used in the Frantz filter.

YUP, that tiny little hole there in the center – about 1/8 inch in diameter is where ALL lube flow must pass on it’s way thru the bypass filter material!

ANYWAY, I use the Frantz filter on my ’02 Dodge … and have been using them for over 40 years – so figure I am as qualified as anyone to show how thay work, as well as a few mods I have done to mine in an effort to improve it.

SOOooo, since I usually prefer to change the TP filter cartridge at 2500 miles or so, today was the day, and I took time to document what is involved. Here’s what the oil on my dipstick looked like prior to the change – and to the wiseguys, YES, there IS oil on that stick, it’s just CLEAN!

Here’s what a used TP roll looks like after 2500+ miles.

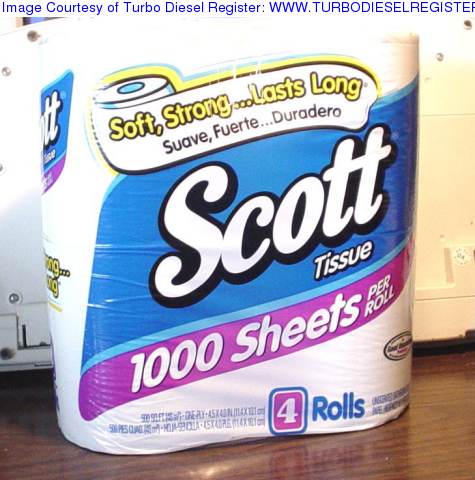

The TP brand I use?

Here’s a shot underhood with the filter canister removed from its base.

You will notice, there is hardly ANY waste oil – I change oil after the truck has been unused for a decent period of time, usually overnight, so most excess oil has had time to drain back into the crankcase.

NOW, as to those “mods” I mentioned, here’s one:

What you see here, is a double thickness of 100-mesh brass screen – this sits at the bottom of the canister with several thicknessses of coffee filter material on top of it. The purpose was to catch any stray paper dust particles that MIGHT shed off the TP rolls from the factory cutting operation – dunno if it helps, but sure doesn’t hurt!

THEN, to help capture any stray iron or other ferrous material, I made a gizmo that inserts into the main lube incoming flow, using a stack of magnets.

Also note the neoprene O-rings around the filters center post – those were selected to provide a snug fit between the TP inner core, and that center post, to prevent any lube from migrating down the center instead of THRU the TP roll – it works nicely, and you can actually see the embossing from those O-rings on the inner surfce of the TP roll where oil pressure has compressed the TP cartridge against them.

Here’s a better shot of the O-rings, as well as showing the new coffee filter material installed prior to reassembling the filter:

So how do you actually install the new TP into the canister? Well, after wiping it out carefully, you must carefully remove enough wraps of TP off the roll to create very snug – actually TIGHT – fit into the canister.

Here’s where it is EXTREMELY important to carefully select a TP material that is wound VERY tightly on the core – density is the important factor here, not “softness” – and deep embossing and perfumes are not wanted here either! Consider the TP not as bunch of loose individual sheets, but as a solid dense filter CARTRIDGE that the oil must travel thru lengthwise before being returned to the engine…

Heres the TP being forced into the canister after trimming the outer unwanted layers off.

Good strong pressure, and a slight twisting motion gets it done… And then reinstall on the filter base – and ready to head on down the road – with VERY clean oil!

Are these Frantz filters for everyone? Probably not, even without the “extras” I have done to mine, they require more care and attention than some of the spin-on bypass filters available from places like Amsoil – and while the Frantz and other similar paper towel Bypass filters are normally quite simple to service, someone CAN select the wrong filter material, and then install it poorly – and then whine endlesly about the poor quality of the filter itself – just s they do with other similar accessories. BUT, if you want clean oil second to none, and are willing to put in just a LITTLE extra effort, these sure do work nice – you DID see my dipstick back in the lead post, didn’t you…?

[thanks to Gary K7GLD and TDR]