One of the most frequent questions I get on the Cummins powered Dodge trucks is transmission related. The Dodge automatic tranny is very robust and does what it was intended to do very well. But given the reputation for massive torque that the Cummins engine provides, many times the transmission is asked to do far more that the engineers at Dodge designed it to do. The best thing you can do to make the transmission last a LONG time is 1) Don't exceed what is recommended in towing, 2) Change, change, change that tranny fluid and filter, 3) keep the bands adjusted. What? you did not know that the Chrysler rear wheel drive units required periodic band adjustments?

Both Ford and GM use a different system that does not require band adjustment. Just think about it like the comparison between hydraulic and sold cam lifters. One needs adjustment and one does not. But when a solid lifter engine is adjusted properly, just you watch out!

I recommend a fluid change at 10k if you tow heavy. Fluid is cheap compared to rebuilding a tranny. I had a friend some time ago that rebuilt trannys for a living and asked him this. What is the one thing that would put you out of business? He said people changing their fluid often. Automatics get a bad rap, but most people I query on their change intervals brings up one glaring fact. THEY DON’T CHANGE THEIR FLUID OFTEN ENOUGH!

So lets talk band adjustment. The front and rear bands need adjusting at every 24k miles with your fluid change. If heavy towing I would cut that in half. It is an easy procedure once you see how it is done. So follow along with the pics and let me show you how its done….

Keep in mind that these adjustments were done on a 98 24v truck. Depending on the year

Band adjustments for each model year: These were borrowed from the TDR page.

1994

Front Band – tighten to 72 in-lb, back off 2-1/2 turns

Rear Band

– 32/42RH – Tighten to 72 in-LB, back off 4 turns<

– 36/37/46/47RH – Tighten to 72 in-lb, back off 2 turns

1995

Front Band

– 42RH – tighten to 72 in-lb, back off 2-1/4 turns

– 46RH – tighten to 72 in-lb, back off 2-7/8 turns

– 47RH – tighten to 72 in-lb, back off 1-7/8 turns

Rear Band

– 42RH – tighten to 72 in-lb, back off 4 turns

– 46RH – tighten to 72 in-lb, back off 2 turns

– 47RH – tighten to 72 in-lb, back off 3 turns

1996

– Front Band – tighten to 72 in-lb, back off 2-7/8 turns

– Rear Band – tighten to 72 in-lb, back off 2 turns

1997 [From: "Paul R. Haller" To: DiRT] Front Band

– 46RE – tighten screw to 8N.m or 72 inch pounds, back off 2 7/8 turns

– 47RE – tighten screw to 8N.m or 72 inch pounds, back off 1 7/8 turns

Rear band

– 46RE – tighten screw to 8N.m or 72 inch pounds, back off 2 turns

– 47RE – tighten screw to 8N.m or 72 inch pounds, back off 3 turns

NOTE: The adjustment screw inside the case is a square head bolt. You will need a special 1/4 square head socket to fit your torque wrench.

1998 unknown

1999

Front Band

– 47RE – tighten band adj. screw to 72 inch pounds, back off 1 7/8 turns

– 42 RE – The final adjustment for the front band has been changed to: back off 3 turns. (TSB 21-16-98)

Rear Band

– 47RE – tighten band adj. screw to 72 inch pounds, back off 3 turns

– The 47RH rear band requires a 1/4" hex driver, the front band requires a T-30 Torx driver, the filter is held in place by two screws which require a T-20 Torx driver

2000-2001

Front Band

– 42RE – Tighten to 72 in-lb, back off 3 turns

– 44RE – Tighten to 72 in-lb, back off 1 7/8 turns

– 46RE – Tighten to 72 in-lb, back off 2 7/8 turns

– 47RE – Tighten to 72 in-lb, back off 1 7/8 turns

From Bill Konolday's 47RE notes: I usually go a little looser than factory specs on this front band – backing off the adjustment screw 2 or 2 1/4 turns. Depending on the circumstances I have backed off the band up to 2 1/2 turns.

Rear Band

– 42RE – tighten band adj. screw to 72 inch pounds, back off 4 turns

– 44RE – tighten band adj. screw to 72 inch pounds, back off 4 turns

– 46RE – tighten band adj. screw to 72 inch pounds, back off 2 turns

– 47RE – tighten band adj. screw to 72 inch pounds, back off 3 turn

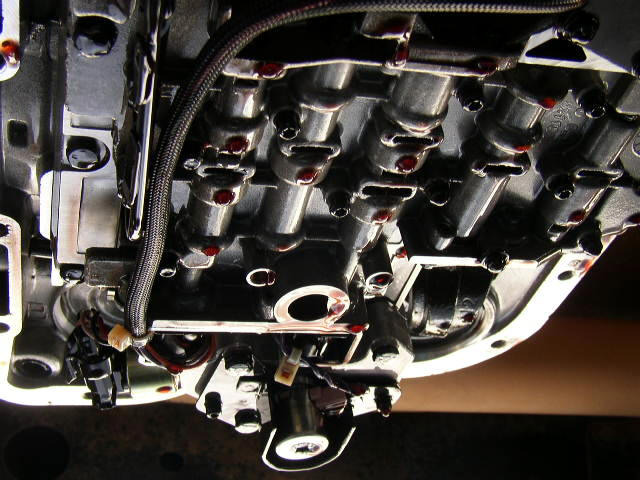

These 2 pics show the lock nut and the adjusting torx T-40 screw.

This is the front band adjustment on the driver's side of the transmission.

Disengage the spring from the lever so your wrench will have some working room.

< p>Back off the nut about 5 turns and then torque the torx screw to 72 inch lbs. Then

< p>Back off the nut about 5 turns and then torque the torx screw to 72 inch lbs. Then

I backed off the torx screw (1 7/8 turns). You must do this! Failure to back off the torx will result in transmission damage! Then re-torque the nut 30ft lbs. Don't forget to re-attach the spring to the lever. Remove the tranny pan and filter to access the rear band adjustment.

Back off the nut about 5 turns and torque the torx screw to 72 inch lbs. Then I backed off the torx screw (3 turns). You must do this! Failure to back off the torx will result in transmission damage! Then re-torque the nut 25ft lbs.

Install the new filter and pan, refill with ATF+4 and enjoy

[thanks to Diesel Giant & TDR dieselgiant.com used with permission]

One Trackback

[…] the bands. Don't worry that the article says 24V; it has all the model year 2nd gens in there. http://dieseldatabase.com/24v-transm…nd-adjustment/ Get fluid and filter and a drain plug kit at the auto parts store. Something like this one. […]