This mod article will walk you through the steps of installing a Fast Idle Switch.

Application: ’05 6.0 PSD with Torque Shift Transmission.

Tools Required:

- 10mm socket with extension and ratchet

- Wire striper, cutter, crimp tool

- At least 5 feet of wire (12-14 gauge, color is user defined)

- 2 sets of butt or spade connectors for connecting leads to existing harness

- single throw rocker or toggle switch

- appropriate connectors for switch

- recommend a volt/ohm meter

The first step is to find a switch to use. My truck did not come with up-fitter switches. So if you are like me or you don’t wish to use your up-fitter switches for this mod then you will need to find a good 12volt DC switch which is good for at least 1 amp. Next I had to choose a good location for my switch. For me the obvious place was the oval shaped knock-out located on the dash directly in front of the turn signal lever.

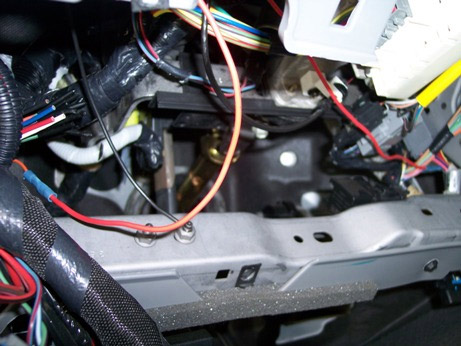

To begin the mod you need to remove the access panel below your steering wheel, simply grasp the handles and give it a manly jerk, the hooks on the bottom are for you to figure it out. (Note: if you can’t get the bottom edge of the panel un-hooked then replace it and have a more mechanically inclined friend do this mod for you). Next use your 10mm socket to remove the four (4) bolts holding the black fuse box to the dash frame, and pull it out of the way.

Now you need to locate which wires you need to use for your switch. Locate the OBD II data port under the dash (off the right front corner of the driver’s seat). Follow the wires on it back into the dash until you come to a white wire with blue stripe.

Strip the end of this wire. Look to the left for the “customer access wiring harness” over the park brake pedal. This is flagged by a large white label which happens to double as a color key (another better idea by Ford). Locate the orange wire with no stripe, again strip the end.

Now I strongly recommend starting the truck, making sure the shifter is in park and the park brake is set. Then bridge these two wires with a length of spare jumper wire with the engine running. After about a second you will notice the engine rev up to 1200 RPM. If it does then you got the correct wires. Hurray! On to the switch, I was able to pull the oval shaped knock-out from my dash by squeezing my hand up behind the dash panel and wrapping my fingers around the top (It has retaining tabs on the top and bottom) I pulled down gently and pushed the top edge out until I could grab it with my other hand and remove it.

Okay this part is tricky and not for the faint of hart. I clamped my knockout in a rubber jawed vise and drilled a small 1/8ths inch hole dead center in it, then I progressively drilled it with larger bits until I reached the size necessary for my particular rocker switch.

After drilling a perfectly centered hole I noticed the backing nut for the switch was too large for the skirt behind the knock-out. So I had to bust out my trusty razor knife and whittle away two notches in the flat sides of the skirt until the nut would fit.

Take a second to admire the craftsmanship :D

Let’s get this puppy together. I used my trusty volt/ohm meter to identify which of the two wires had a positive DC current on it. And which was grounded, this was only important for the nifty LED on my rocker switch to work properly. If your switch isn’t as cool as mine then you can skip the polarity check. Using butt connectors attach wires to the factory wires you striped earlier, making sure they reach your switch location and still have slack for the fuse box to go back in. Lastly in my case I had to include a ground wire for my switch (again with that super pimp LED), which I just wrapped around a bolt on the bottom bar of my dash frame.

Last complete the connections for your switch and finish installing it. If you did every thing right you can start your truck again and flip the switch. Hopefully it still works. If it does slap your truck back together and show it off to your friends if not my number is (555) 555-5555, you can tell me all about how I messed up your truck.

Enjoy!